I would like to know more about my readers. If you could spare about 2 minutes of your time, please take a survey to tell me what you like about the blog. Just click here to take the survey.

This week is a quick post about what may be an interesting trend in the US Land Oil & Gas Sector…Interest in Automation and Optimization technologies to increase efficiencies. I have a theory on why. AND, #Disclaimer, I mention the service offering I work with.

Historic Interest in Automation

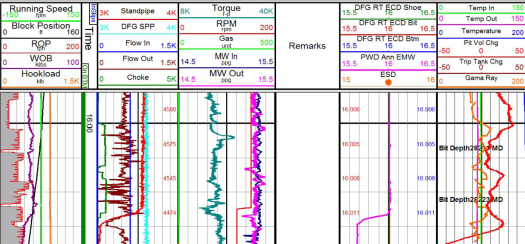

Historically, there are always early adopters for technology, and the oilfield is no different. You have a few entities that want to be on the cutting edge of everything, a few tire kickers, and the majority don’t want to spend any money until something is proven to them. Such is the case with automation and optimization, from the perspective of the offering we have (BaraLogix Equipment & Services).

Offshore

We initially provided the optimization and event detection service offshore. This was before the equipment was ready to ready to be deployed commercially. Actually, it was still in development. We had a few jobs here and there, but not a lot of buy-in. Even with customers that benefitted from significant value from it, it seemed the response was always something similar to “Maybe you actually did help us achieve our goals, but maybe it was something else…” or “We don’t have the authority to sign off on this case history saying that you brought us value.”

So we did jobs here and there, but there was never a consistency to the work.

Land

As far as land work was concerned, due to different economics, the service was always outside the client’s budget. In fact, the only time we did provide the service on land, at least in the US, was when conducting trials of the equipment.

Fast-forward to today…

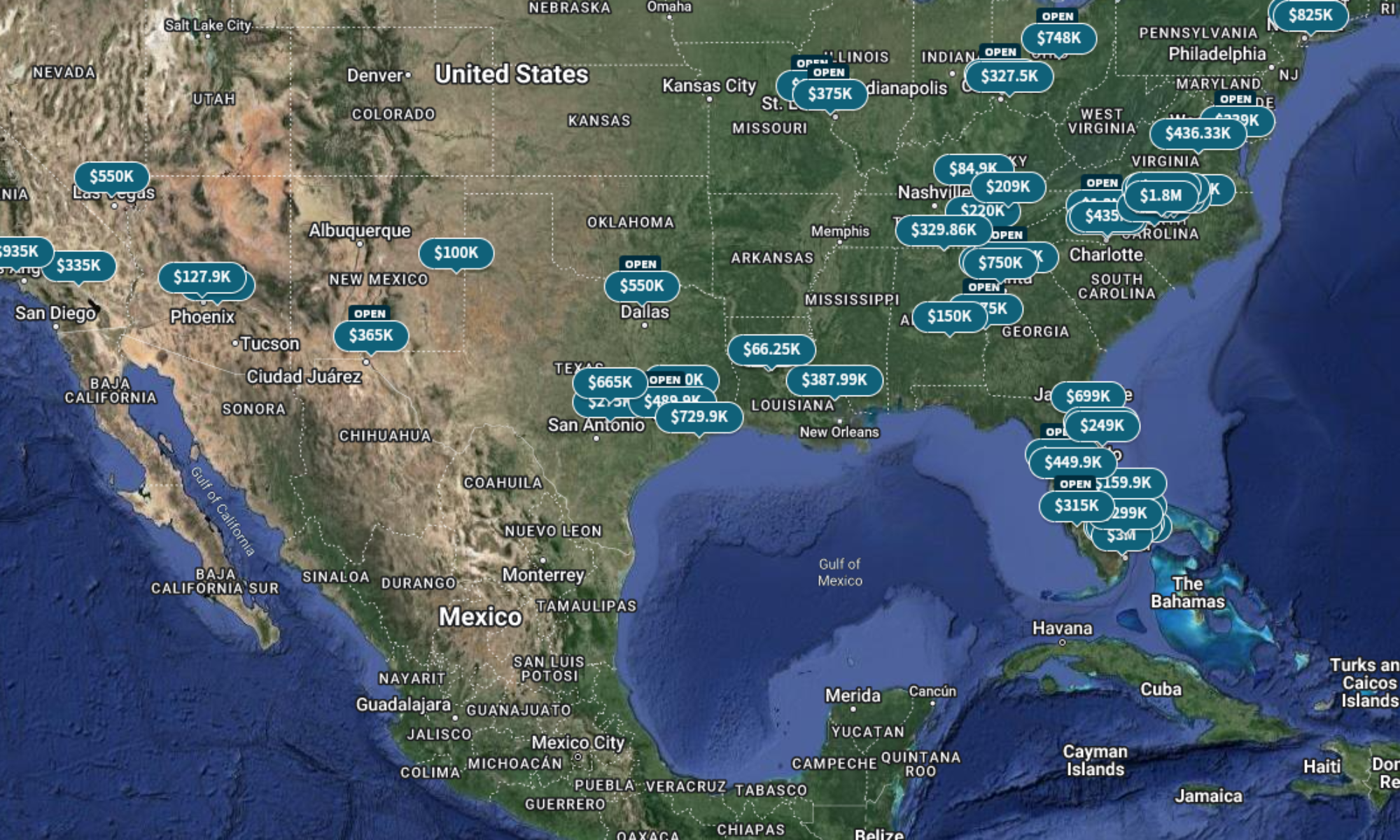

We now have customers in the US Land area that are interested in what the service and equipment can provide them. There are three jobs starting up in the next three weeks or so that are a mix of the combined equipment & services or just the standalone service.

My thoughts jump to “Why now?”

What I suspect is that over the last 3-plus years, operators have been increasing their efficiencies to stay relevant at lower oil prices. And possibly they have plateaued. Now, they want to take that next step and increase efficiencies even more. I think that may play a big part in the sudden interest in our equipment and services.

What do YOU think could be driving this?

And, as always, let me know what you think in the comments. Ask questions, tell your story.

If you like my posts, please share them with others and subscribe to this blog.